|

|

1 OSYRIS Product Description and Pricing

1.1 OSYRIS Standards

OSYRIS Standards is a set of several pre-standards describing the format and contents of exchange of information between the OSYRIS components.

Disclosing and promoting these standards allows other systems to comply with existing OSYRIS-components and ensures a broader acceptance of the OSYIRS products.

The standards are fourfold, referring to the three different interchange levels:

1. Machine to Design & Documentation:

OSYRIS Machine <--> OSYRIS Design & Documentation.

2. Inter Machine Communication Standard:

OSYRIS Machine <--> OSYRIS Machine.

3. On Board Computer Communication Standard: Describing the data

handling inside the onboard computer Software.

4. On Machine Communication Standard: Communication Standard for

different components on the machine.

|

|

Four types of OSYRIS-Standards

OSYRIS Standards build up the backbone of OSYRIS in terms of communication between components.

Disclosure of these standards will allow new and existing products to use this communication possibilities and taking benefit of other OSYRIS-components.

OSYRIS standards is strongly promoted among machine manufacturers, contractors and authorities.

|

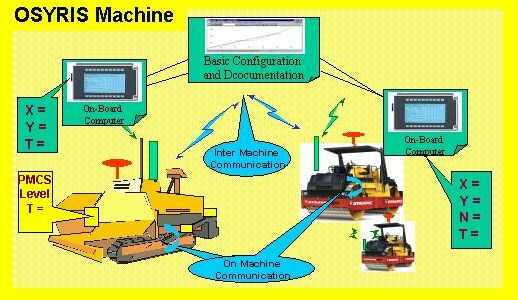

1.2 OSYRIS Machine

OSYRIS Machine addresses the basic needs of a contractor for support of paving and asphalt compaction work.

It consists of four compliant groups of components:

On Board Computers for Paver and Roller

Paver Measurement and Control System, PMCS, sensors and control

Basic Configuration and Documentation Tool

It is configured for a typical asphalt laying team: 1 paver and 2 rollers.

|

|

OSYRIS Machine for the paver

rough positioning

material core temperature

communication to the rollers

on-board computer

|

OSYRIS Machine for 2 rollers:

passes counting

thickness computed (measured, optional),

cooling model: estimate of asphalt temperature

positioning of roller

mobile services

on-board computer for documentation

|

| OSYRIS Machine includes tools for Basic Configuration and Documentation to

Plan the work (most important functionalities)

Basic documentation of construction process

Macros for post processing.

|

OSYRIS machine can be completed with a variety of optional components for more sophisticated applications gathered within OSYRIS machine extensions.

1.3 OSYRIS Machine Extensions

OSYRIS Machine Extensions is a set of options to extend the basic configuration OSYRIS Machine.

thickness

evenness

material temperature,

wind speed,

air temperature,

surface temperature

width

3D levelling

Compactor options:

precise cooling model

precise positioning

rolling resistance

surface temperature

OSYRIS machine extensions are in case of the paver prototypes that are already tested and will be in advanced product prototype stage at the end of the project. In case of the roller they are still under development, but will be tested and validated under laboratory and worksite conditions to get into product prototype stage.

Industrialisation distribution through OEMs will be carried out by Moba including adaptations based on bi-laterally developed product implementation strategies, as every OEM will follow own strategies.

For retrofitting and marketing approaches towards contractors industrial partner(s) is/are needed. Therefore Positioning Manufacturers and firms operating in this domain like PG:ES are approached by the OSYRIS-partners UKA/TMB and MOBA.

Actually there are about 1000 big pavers used in Europe with an annual renewal rate of about 10%.

The actual market of large worksites with precise 3D positioning (high end market) is at about 3% of new machines. Therefore about 3 OSYRIS-machine extensions systems could be sold annually regarding the OEM Market.

Between the low end (OSY-M- minimum implementation) and high end version (all sensors implemented together with high accurate DPGS- system) we expect an evolving market for OSYRIS products with about 2% yearly rate of increase after 2 years of the end of the OSYRIS project.

Retrofitting Market.

1.4 OSYRIS design and documentation

OSYRIS design and documentation consists of software for support of the road design process and documenting the final road as well as the construction process. The software is modular and all of it is based on the platform (Tekla Xstreet product) and technology. The technology is the same that is used in all other Tekla products.

The road design functionality is based on product model approach (not cross sections, but continuous geometry and rules) and supports all phases of road construction from data collection to documenting and distributing the designed road. The system relies completely on standard commercial relational databases for data storage and management. Potential customers for these products are Consulting engineers, national road administrations and city councils.

The documentation functionality provides following

an extended product model to store the data retrieved during the road construction process (mainly trough the interface provided by OSYRIS standards, also manual entry)

functionality to report and present this information in different ways both off and on-site

long term data management functionality to store and utilise the data on a long term basis

Potential customers for documentation include road owners (national road administrations, city councils and big corporations) and road constructors.

|

|

|

|